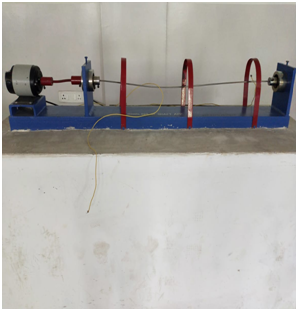

Theory of machine lab:

Objectives of Theory of Machines lab are to impart practical knowledge on design and analysis of mechanisms for the specified type of motion in a machine. With the study of rigid bodies motions and forces for the transmission systems, machine kinematics and dynamics can be well understood. It deals with the study of relative motion between the various parts of a machine and forces which act on them. In this lab apparatus is used like Motorized Gyroscope Apparatus, Journal Bearing Apparatus, whirling of shafts demonstrator, universal governor etc.

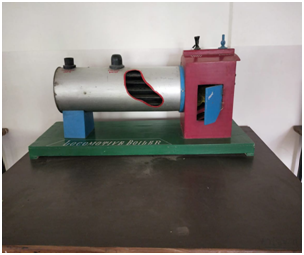

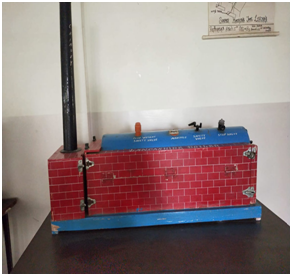

Thermal lab :

The objective of this lab is to understand the basic principles in the areas of internal combustion engines, boilers and Refrigeration systems to under graduate and Post graduate students through a series of experiments. In this lab the experiments are performed to measure performance parameters of the systems such as Brake power, Efficiency, Torque , COP, mass of fuel. Students have a fairly good understanding of the theory underlying the experiments and the entire lab course is designed such that classroom lectures precede the lab work. The Thermal Engineering Laboratory is equipped with test facilities for doing research with in internal combustion engines for energy conversion.

Strength of material and Mechanics lab:

Theobjective of the strength of material lab is to demonstrate the basics principle in the area of strength and mechanics of material structural analysis in this lab the experiments are performed to measure the properties of materials such as impact strength, tensile strength, compressive strength hardness ,ductility etc.Major equipments are Universal Testing machine(UTM), Impact Testing Machine, Brinell hardness testing machine, Rockwell hardness testing Machine etc.

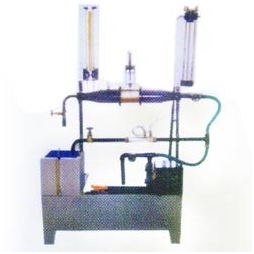

Fluid Mechanics lab:

The objective of this laboratory is to determine the various parameter related to fluid flow in pipes and in open channels. at present it is equipped with hydraulic benches & various stand-alone equipment to carry out experiment like determination of meta centric height of floating vessel,verification of the Bernoulli’s equation, study of transition from laminar to turbulent flow ,determination of velocity profile from laminar to turbulent flow, determination of coefficient of discharge (Venturi meter/orifice meter),determination of friction coefficient for pipes of various diameter and calculation minor head losses in pipes etc.

Mechanical workshop:

Workshop practise gives the basic working knowledge required for the production of various engineering products. It explains the construction, function, use and application of different working tools, equipment, machines as well as the technique of manufacturing a product from its raw material.

Different Shops available in central workshop are as follows:

Fitting Shop.

Welding Shop.

Machine Shop (Turning, Milling, Drilling, Grinding, Cutting etc)

Blacksmith.

Carpentry.